China wholesale Sheet Rubber Roll – Green red Flooring / gasket use thin 1mm 2mm rubber sheet roll wear resistant – Skypro

China wholesale Sheet Rubber Roll – Green red Flooring / gasket use thin 1mm 2mm rubber sheet roll wear resistant – Skypro Detail:

| Product Name: | Red And Green Rubber Sheet | Color: | Black,red,green,blue Grey Etc. |

|---|---|---|---|

| Width: | Normall 1-2m,maximum 3.8m | Standard: | ROHS/SGS |

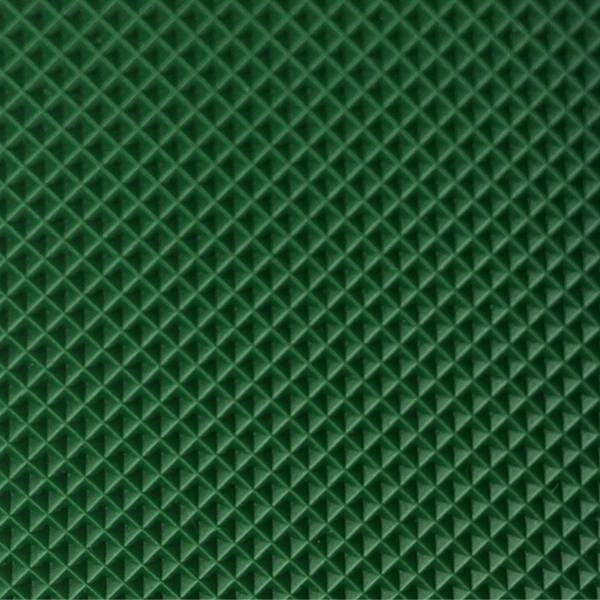

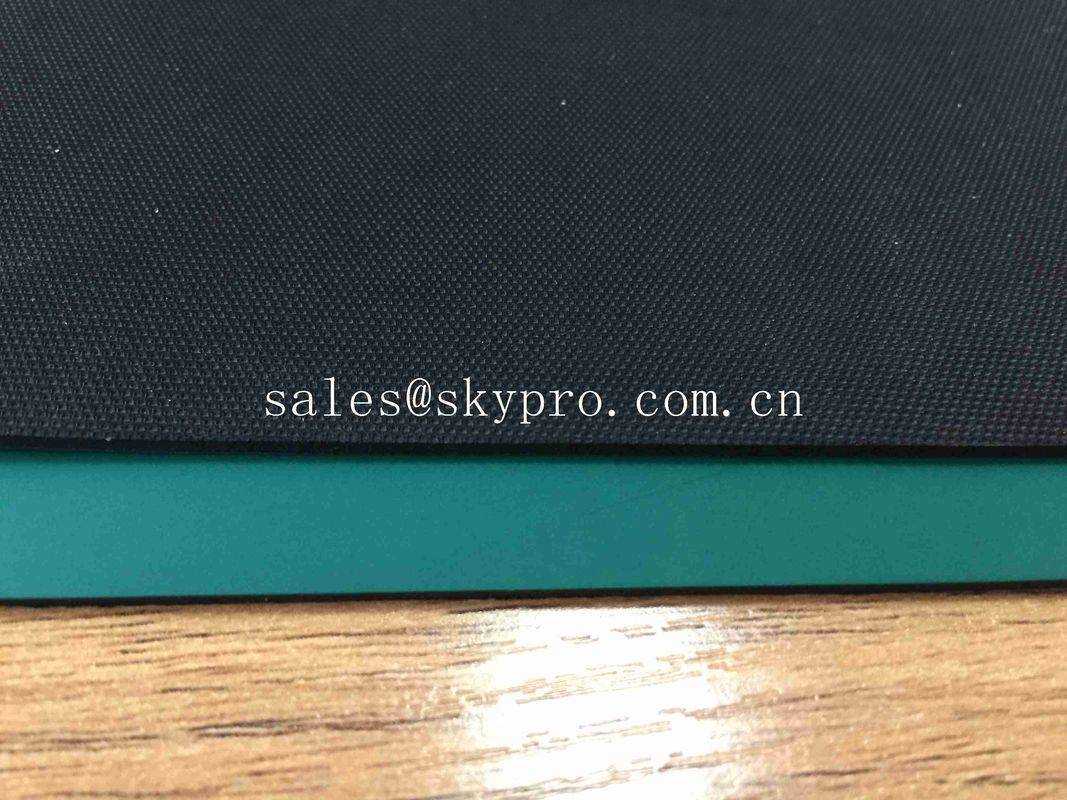

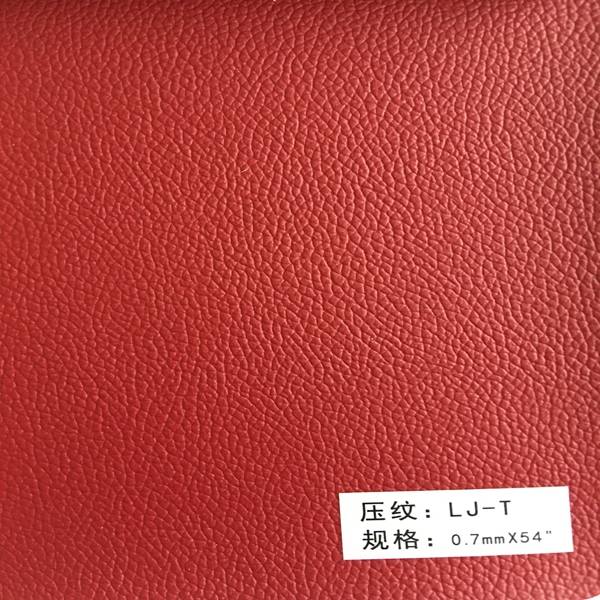

| Application: | Flooring,gasket | Surface: | Smooth,embossed |

| Working Temperature: | -10-80 C | Hardness: | 40-80 Shore A |

| High Light: |

rubber sheeting roll, rubber flooring sheet roll |

||

red and greenrubber sheet roll / colored rubber sheet

Product Name: red green rubber sheet roll

Dimensions: 1-80mmx3700m(TXW)

Density:1.25g/cm3

Tensile strength:>=5MPa

Hardness:50+/-5shore A

Elongation:>=500%

Work temperature:-50-300 C

Application: chemical, foods and pharmacy

Advantages:

Oxidation resistance

Excellent ozone resistance

Non-flammable

Oil resistance

Resistance to acid and alkali

Anti-aging

Applications:

Mainly used in chemical engineering, constructions, autos, machinery, electronics, pharmacy, suitable for punching various sealing ring, buffering, rubber washer, sealing tape and for paving floor, etc.

Packing and transportation:

|

Packing way |

Packed in roll or flat sheet,50-100kg/roll or according to specific requests from clients |

|

Packing material |

Inner PE film+ outer Woven plastic bags as standard, palletized for extra reinforcement if necessary |

|

Shipping marks |

Neutral packing with printed marks. |

|

Delivery time |

15 days since receipt of PO and down payment |

|

Freight |

Sea(FCL & LCL) or air freight |

|

Special size |

We provide cutting services for special sizes |

|

Lamination |

We provides extra lamination with PSA, textiles or other materials. |

FAQ(Frequently Asked Questions)1. What is the capability of your company ?Skypro is a professional manufacturer of rubber sheet for more than two decades.Top 10 biggest rubber factory in China.2.What is production capability each year?We produce more than 18000 tons of rubber sheet products each year.3.How can I get some samples?We are pleased to offer you free samples. New clients are expected to pay for the delivery cost, this charge will be deducted from the payment for formal order.

About Rubber

|

rubber variety(ASTM ) |

IR |

SBR |

BR |

CR |

NBR |

|

|

chemical structure |

Isoprene Rubber,Cis 1,4- Polyisoprene “Synthetic Natural Rubber” |

Styrene Butadiene Rubber |

Polybutadiene Rubber |

Poly-2-chlorobutadiene -1,3 chloroprene Rubber, Neoprene |

Butadiene Acrylnitrile Rubber,Nitrile Rubber |

|

|

main characteristics |

high flexibility, good comprehensive physical mechanic performance |

better wear-resistant and anti-aging function than NR, lower prices |

same wear-resistant with NR and better flexible and lower temperature resistant than NR |

good climate resistant, ozone proof, hot resistance and chemical resistant |

good oil-resistant, wear-resistant and anti-aging |

|

|

quality of NR |

proportion |

0.93 |

0.94 |

0.93 |

1.23 |

0.96~1.02 |

|

meni adhesive meni adhesive ML1+4100 ℃ |

45 ~150 |

30~ 7 0 |

35~55 |

45~120 |

30~100 |

|

|

rubber physical performance |

hardness range ( SHORE A ) |

2 0~100 |

4 0~100 |

30~100 |

45~120 |

30~130 |

|

anti-tensity (MPa) |

7~27 |

7~24 |

7~20 |

7~27 |

7~27 |

|

|

elongation rate (%) |

100~ 700 |

100~ 700 |

100~ 700 |

100~ 600 |

100~700 |

|

|

re-elasticity |

excellent + |

good |

excellent + |

excellent |

good |

|

|

tearing force |

excellent |

middle ~ good |

good |

good |

good |

|

|

wear-resistant |

excellent |

excellent |

excellent |

excellent |

excellent |

|

|

compress & distortion |

good |

good |

middle |

good |

good |

|

|

temperature range(℃) |

-75~90 |

-60~100 |

-100~100 |

-50~120 |

-50~120 |

|

|

climate resistant |

middle |

middle |

middle |

excellent |

bad |

|

|

ozone proof |

bad |

middle |

bad |

good ~ excellent |

middle |

|

|

electric performance |

excellent |

middle |

good |

good |

bad ~ middle |

|

|

gas penetrating resistant |

middle |

middle |

middle |

good |

excellent |

|

|

oil-resistant and acid& alkali resistant |

oil-resistant |

bad |

bad |

bad |

good |

excellent |

|

fire-resistant |

bad |

bad |

bad |

middle |

good |

|

|

alcohol |

excellent |

excellent |

excellent |

excellent |

excellent |

|

|

MEK |

good |

good |

good |

good |

middle |

|

|

water |

excellent |

good ~ excellent |

bad |

good |

excellent |

|

|

high concentration inorganic acid |

middle |

bad |

bad |

middle |

middle |

|

|

low concentration inorganic acid |

good |

good |

good |

excellent |

good |

|

|

high concentration alkali |

good |

good |

good |

excellent |

good |

|

|

low concentration alkali |

good |

good |

good |

excellent |

good |

|

|

application |

tyre, rubber shoes, rubber pipe, adhesive tape, air spring |

tyre, rubber shoes, rubberized fabrics, sports products, mattress, accumulator shell, adhesive tape |

car & air plane tyre, rubber shoes, shock absorber rubber, adhesive tape, rubber pipe |

wire sleeve, conveying line shock absorber rubber, window & door wedge, rubber adhesives, rubberized fabrics |

oil seal, washer, oil-resistant rubber pipe, printing rubber roller, textile leather roller |

|

|

rubber variety(ASTM ) |

EPDM |

IIR |

CSM |

SIR |

FKM |

|

|

chemical structure |

Ethylene Propylene Terpolymer Rubber |

Isobutene-Isoprene (butyl) Rubber |

Chlorosulfonated Polyethyelene |

Silicone Rubber |

Vinylidene Fluoride Hexaflyoropropylene Rubber,Viton |

|

|

main characteristics |

good anti-aging, ozone proof, polar liquid resistant, good electric performance, lightest rubber |

good climate resistant, ozone proof, gas penetrating resistant, polar solvent resistant |

better wear-resistant and anti-aging function than NR, lower prices. |

good cold & hot resistant |

best hot resistant and chemical resistant |

|

|

quality of NR |

proportion |

0.85 |

0.91~0.93 |

1.10 |

0.98 |

1.4~1.96 |

|

meni adhesive ML1+4100 ℃ |

40~100 |

45~80 |

45~60 |

liquid state |

35~160 |

|

|

rubber physical performance |

hardness range ( SHORE A ) |

30~100 |

20~90 |

50~95 |

20~95 |

60~90 |

|

anti-tensity (MPa) |

7~20 |

7~20 |

7~20 |

3~10 |

7~16 |

|

|

elongation rate (%) |

100~300 |

100~700 |

100~500 |

50~800 |

100~350 |

|

|

re-elasticity |

good |

middle |

good |

good |

middle |

|

|

tearing force |

bad |

excellent |

good |

middle |

middle |

|

|

wear-resistant |

good |

good |

good |

middle |

good |

|

|

compress & distortion |

middle |

middle |

good |

excellent |

excellent |

|

|

temperature range(℃) |

-60~150 |

-60~150 |

-60~150 |

-120~280 |

-50~300 |

|

|

climate resistant |

excellent |

excellent |

excellent |

excellent |

excellent |

|

|

ozone proof |

excellent |

excellent |

excellent + |

excellent |

excellent + |

|

|

electric performance |

excellent |

excellent |

good |

excellent |

good ~ excellent |

|

|

gas penetrating resistant |

middle |

excellent |

less good |

bad |

excellent |

|

|

oil-resistant and acid& alkali resistant |

oil-resistant |

bad |

middle |

good |

middle |

excellent |

|

fire-resistant |

bad |

bad |

middle |

bad |

excellent |

|

|

alcohol |

excellent |

excellent |

excellent |

excellent |

excellent |

|

|

MEK |

good |

excellent |

less good |

excellent |

middle |

|

|

water |

excellent |

excellent |

good ~ excellent |

excellent |

good ~ ecellent |

|

|

high concentration inorganic acid |

good |

excellent |

excellent |

good |

excellent |

|

|

low concentration inorganic acid |

excellent |

excellent |

excellent |

excellent |

excellent |

|

|

high concentration alkali |

excellent |

excellent |

excellent |

excellent |

excellent |

|

|

low concentration alkali |

excellent |

excellent |

excellent |

excellent |

excellent |

|

|

application |

wire sleeve, auto weather strip, window & door wedge, steam rubber pipe, conveying line |

interior tyre, sulfuration capsule, roof materials, wire sleeve, window & door wedge, steam rubber pipe, hot resistant conveying line |

climate resistant, anti-corrosion coating, tank lining, outdoor rubberized fabrics, anti-corrosion axe seal, rubber roller |

axe seal, washer, industrial rubber roller, shock absorber product, insulation products, medical products |

axe seal used in rocket, missile, septum, tank lining, front pipe and pump fittings used in chemical factory |

|

Tolerance Table

specification tolerance range:

|

thickness |

width |

||

|

metric size |

tolerance |

metric size |

tolerance |

|

±0.1 |

500~2000 |

±20 |

|

|

1.0 |

±0.2 |

||

|

1.5 |

±0.3 |

||

|

2.0 |

|||

|

2.5 |

|||

|

3.0 |

±0.4 |

||

|

4.0 |

±0.5 |

||

|

5.0 |

|||

|

6.0 |

±0.6 |

||

|

8.0 |

±0.8 |

||

|

10 |

±1.0 |

||

|

12 |

±1.2 |

||

|

14 |

±1.4 |

||

|

16 |

±1.5 |

||

|

18 |

|||

|

20 |

|||

|

22 |

|||

|

25 |

|||

|

30 |

|||

|

40 |

|||

|

50 |

|||

technical index tolerance range:drawing intensity:≥ MPaproportion:±0.05g/Cm3hardness:±5shoreAextending:≥ %

Product detail pictures:

Related Product Guide:

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for China wholesale Sheet Rubber Roll – Green red Flooring / gasket use thin 1mm 2mm rubber sheet roll wear resistant – Skypro , The product will supply to all over the world, such as: Kuala Lumpur, The Swiss, Grenada, We have customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Should you need anything, don't hesitate to contact us.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.