Die Cut Closed Cell Foam Rubber Sheets , High Elastic Resilience Eva Slipper / Eva Sandles

| Material: | EVA | Thickness: | According To Your Requirement |

|---|---|---|---|

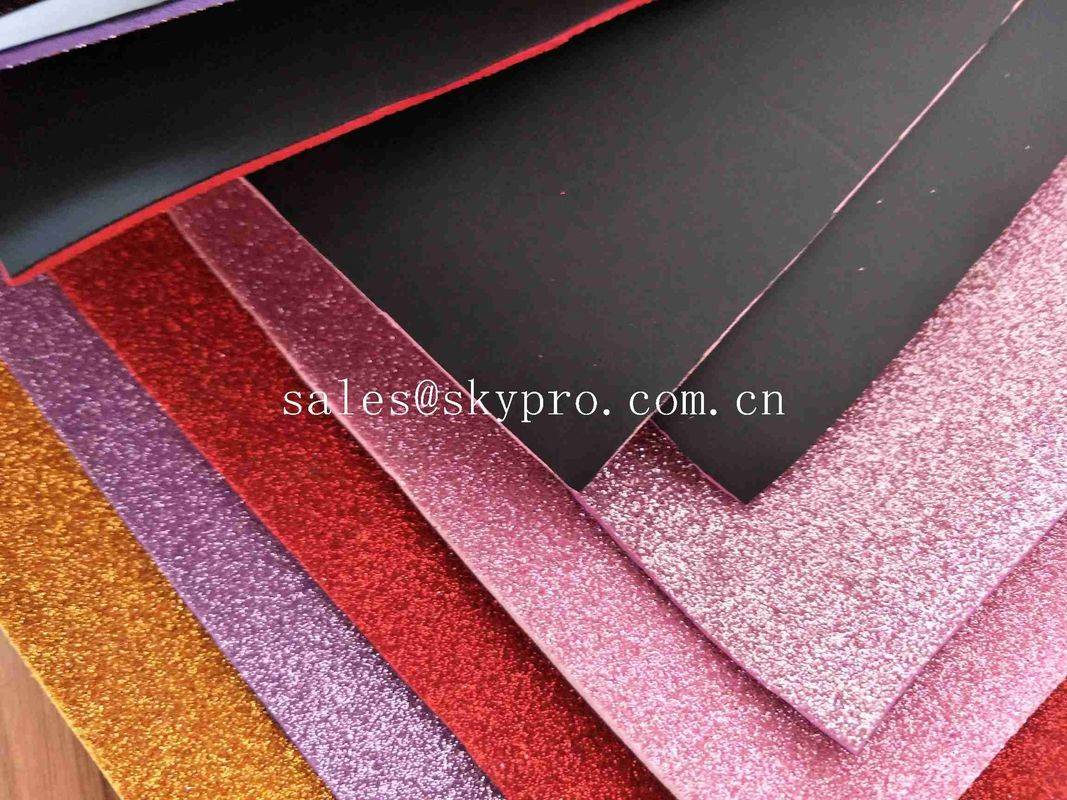

| Hardness: | 20-90 Shores | Color: | Any Color Is Available |

| Size: | Any Size | Prinitng Are Accepted.: | Yes |

| High Light: |

foam rubber sheets, EVA sole sheet |

||

Specification:

1. material:EVA2. any size3. thickness:According to your requirement.

4. hardness :20-90 shores5. color:any color is available

6. Prinitng are accepted.

7. Good quality and environmental protection.

8. Application:Widely used in puzzles,EVA floor,resting cushions,children's toy ,shoes and Yoga mat etc.

9. package:poly bag

10.Terms of payment: L/C ,T/T

11. Delivery time :20 days

12. Packing;in rolls or flat sheets , inner PE film +outer woven plastic bags

|

spec:1m*2m |

|||||||

|

examination project |

unit |

name |

|||||

|

L-1500 |

L-2000 |

L-2500 |

L-3000 |

L-4000 |

|||

|

tensile strength at break |

mpa |

0.25-0.3 |

|||||

|

elongation at break |

% |

240-290 |

220-250 |

180-230 |

170-200 |

150-180 |

|

|

ASKER“C”hardness |

° |

40-45° |

30-35° |

20-25° |

15-20° |

12-15° |

|

|

tear strength |

KN/M |

7-10 |

8.5-11 |

9-12 |

|||

|

density |

Kg/m 3 |

60Kg/m 3 |

50Kg/m 3 |

40Kg/m 3 |

30Kg/m 3 |

25Kg/m 3 |

|

|

compression set |

% |

54.2 |

|||||

|

compression set |

Ø23mm specimen |

% |

0.2percent of pass94% |

0.2percent of pass94% |

0.2percent of pass94% |

0.2percent of pass94% |

0.2percent of pass94% |

|

24h*25% |

50*50mm specimen |

% |

|||||

|

combustion test(straight) |

B1 |

32 |

32 |

32 |

|||

|

B2 |

26 |

26 |

26 |

||||

|

ignitability |

≤150 |

||||||

Description:

EVA foam(Ethylene Vinyl Acetate) has a closed cell structure,it is an extremely versatile material suitable for a broad range of different uses and applications. EVA material is an effectie replacement for many materials including felt, neoprene, natural rubber, polyurethane foam, pvc foam, wood composites, mineral wool and fibreglass.EVA foam can be used for children manual craft, toy and shoe sole material,thermoforming,die cut or compress formed logos,screen printing,thermal transfer printing,vacuum form and glue coated ,etc.

Feature:

1) Water resistance: The closed cell structure, does not absorb water, moisture-proof, good water resistant performance;2) Anti-corrosion: resist sea water, grease, acid, alkali and other chemical corrosion;3) Eco-friendly:non-toxic, tasteless, antibiosis ,no pollution;4) Workability: easy to process for stamping,cutting,gluing,plying-up,etc.;5) Anti – vibration: high elastic resilience and stretching resistance,strong toughness, good quakeproof/cushion performance;6) Heat preservation: outstanding heat insulation, heat preservation, cold-resistance and good performance in low temperature ,resist severely cold and hot exposure;7) Sound insulation:closed cell structure, good sound-insulated effect;8) Elasticity:better elongation and elastic resilience than other materials.

Application:Household appliances, hardware tools, toys, crafts, tourism products, stationery, cosmetics,The skates,

shoes, sports lining materials back cushion, bags, mat mat; the knees surfboard,Sports equipment, automobile interior trim, shoes joint,High-grade foam tape products base material,Cold storage, protection construction,

light roofs, construction and installation construction adiabatic materials; etc.Car seat, roof, foot pad, sunvisors materials,Electrical appliances, precision instrument, equipment, and other electronic products, shockproof

cushion packaging field.