Good Quality Rough Top Conveyor Belt - PU TPU PE TPEE plastic Conveyor belt for wood processing industry – Skypro

Good Quality Rough Top Conveyor Belt - PU TPU PE TPEE plastic Conveyor belt for wood processing industry – Skypro Detail:

| Features: | Wear Resistant,high Tensile Strength,low Noise | Material: | PVC,PU,TPU, PE, TPEE, Teflon, Silicone |

|---|---|---|---|

| Structure: | Flat Grip Belt | Conditions: | New |

| Colors: | Green,Black,White,Blue And Other | Width: | 3.5m Max. |

| High Light: |

PVC PU conveyor belt, plastic conveyor belt |

||

Conveyor belt for wood processing industry

The light duty conveyor belt we provide for wood processing industry can be widely used for artificial wood (high, middle density board, plywood, fiberboard, shaving board, composition board etc.),flooring production line as well as variety of mechanical equipments.

The different material, thickness and texture defines the adhesion, physical ,chemical and mechanical property. Meanwhile, the difference of textile material quality greatly decides the application range of the belt.

We use wear resistant surface coated belt to enable durable on surface, and use high strength textile fibers to reinforce the stability and strength of the belt.

Due to the specialty of belt structure, it come up with a lot of excellent property such like low stretch, dimensional stability, low noise and long durability.

Conveyor belt for wood processing industry

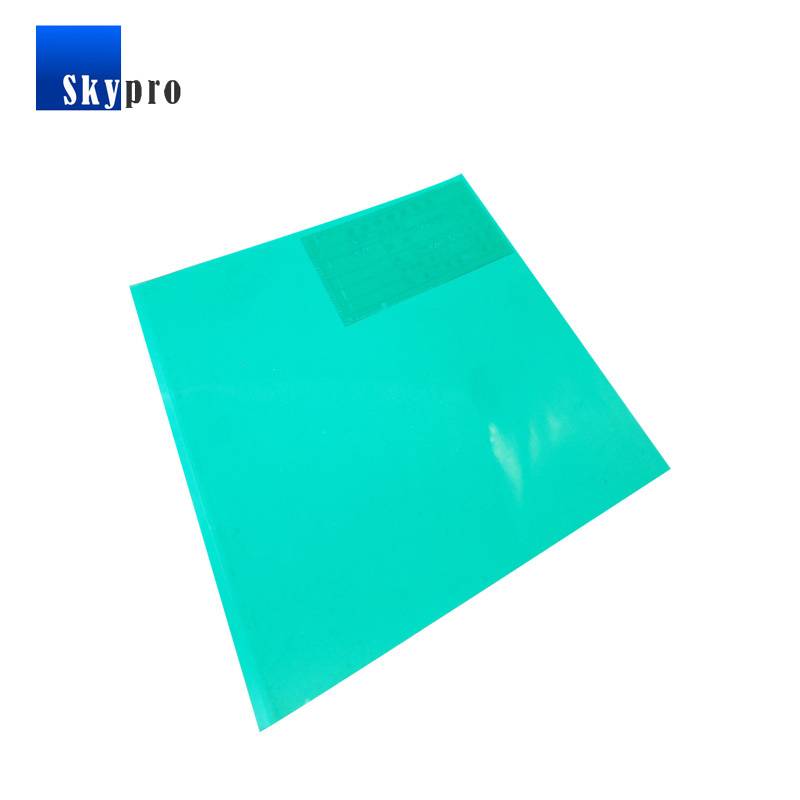

Model: SP39-76

Total thickness:5.5mm

Top coating thickness:2.0mm

Color: deep aquamarine

urface finish: plain flat (shiny or matt ) ,chevron, rough, diamond, rib, grid etc.

Weight:6.8kg/m2

Tensile force for 1% elongation:45N/mm

Top hardness:75 Shore A

Minimum pulley diameter:250mm

Maximum production width: 2800mm

Suitable machine type: pre-pressing machine

Model: SP42-14

Total thickness:5.5mm

Top coating thickness:1.0mm

Color: green

Weight:5.5kg/m2

Tensile force for 1% elongation:25N/mm

Top hardness:75 Shore A

Minimum pulley diameter:150mm

Maximum production width: 3000mm

Suitable machine type: pre-pressing machine

Model: SP32-36/13

Total thickness:9.5mm

Top coating thickness:6.0mm

Color: blue

Weight:8.5kg/m2

Top hardness:75 Shore A

Tensile force for 1% elongation:15N/mm

Minimum pulley diameter:120mm

Maximum production width: 2000mm

Suitable machine type: polishing machine

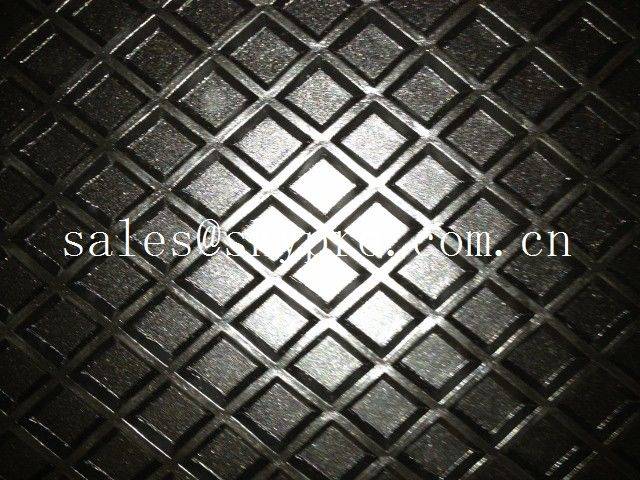

Model: SP32-36/28

Total thickness:9.0mm

Top coating thickness:5.5

Color: black

Weight: 8.9kg/m2

Top hardness:55 Shore A

Tensile force for 1% elongation:15N/mm

Minimum pulley diameter:120mm

Maximum production width: 2000mm

Suitable machine type: polishing machine

Model: SP22-46/14HD

Total thickness:5.5mm

Top coating thickness:3.5mm

Color: grey

Weight: 5.2kg/m2

Top hardness:65 Shore A

Tensile force for 1% elongation:10N/mm

Minimum pulley diameter:100mm

Maximum production width: 2000mm

Suitable machine type: polishing machine

Model: SP32-36/13

Total thickness:9.5mm

Top coating thickness:6.0mm

Color: black

Weight: 8.5kg/m2

Top hardness:50 Shore A

Tensile force for 1% elongation:15N/mm

Minimum pulley diameter:120mm

Maximum production width: 2000mm

Suitable machine type: polishing machine

Model: SP22-76/3D

Total thickness:5.0mm

Top coating thickness:3.5mm

Color: deep aquamarine

Weight: 5.2kg/m2

Top hardness:55 Shore A

Tensile force for 1% elongation:10N/mm

Minimum pulley diameter:50mm

Maximum production width: 2000mm

Suitable machine type: polishing machine

Model: SP25-14BA

Total thickness:1.6mm

Top coating thickness:0.3mm

Color: green

Weight: 1.6kg/m2

Top hardness:75 Shore A

Tensile force for 1% elongation:8N/mm

Minimum pulley diameter:20mm

Maximum production width: 3000mm

Model: SP25-74/0

Total thickness:2.0mm

Top coating thickness:0.5mm

Color: deep aquamarine

Weight: 2.3kg/m2

Top hardness:75 Shore A

Tensile force for 1% elongation:8N/mm

Minimum pulley diameter:25mm

Maximum production width: 3000mm

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine consistently for Good Quality Rough Top Conveyor Belt - PU TPU PE TPEE plastic Conveyor belt for wood processing industry – Skypro , The product will supply to all over the world, such as: Swansea, Pakistan, Germany, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.