High Quality Rubber Roll Sheet - Insulation Natural Latex Rubber Sheets High Temp Anti – abrasion Thick Petrol Resistant – Skypro

High Quality Rubber Roll Sheet - Insulation Natural Latex Rubber Sheets High Temp Anti – abrasion Thick Petrol Resistant – Skypro Detail:

| Product Name: | Natural Latex Rubber Sheets | Color: | Red,Etc. |

|---|---|---|---|

| Elongation: | 200%-450% | Density: | 1.3~1.8g/cm3 |

| Feature: | Excellent Resistance | Application: | Transport,Electronic |

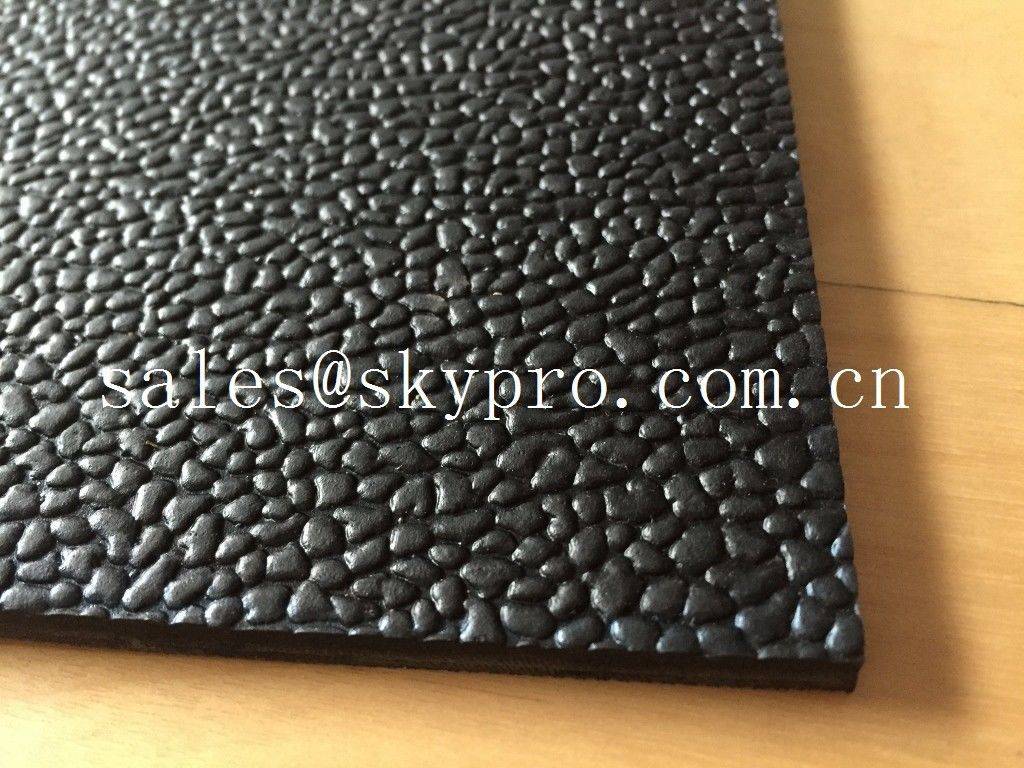

| Surface: | Textured Or Smooth | ||

| High Light: |

rubber sheeting roll, rubber mat roll |

||

High Temp Anti-abrasion Thick Petrol Resistant Insulation Natural Latex Rubber Sheets

Rubber Latex Sheet:

Latex rubber is the purest form of rubber. It has a smooth finish on both sides, high tensile strength and elasticity. Latex rubber can be supplied in food compliant, anti-static and high temperature grades. It is commonly used for bakery release films, diaphragms, seals, gaskets, and vacuum blankets.

Applications:

Vacuum blankets for composite moldings, bonding laminated structures, laminating fabrics and veneers to complex shaped structures, bakery release film, cut diaphragms, seals & gaskets.

Temperature: up to +80ºC

Availability:

| Colors | Natural,black,pink,green,blue,red,purple,white,etc |

| Width | Up to 750mm as standard |

| Thickness | 0.2mm to 3.0mm |

Composition:Natural Rubber plus essential processing chemical and pigments.

Health Hazards:Natural Latex Rubber Sheeting is generally considered non-hazardous. However, the product is manufactured from natural latex and latex products may cause an allergic reaction to some people. Persons who know they are susceptible to an allergic reaction from latex products should avoid contact with Natural Latex Rubber Sheeting.

Fire Hazard:Sheeting should be protected during handling and storage from naked flames as rubber is flammable. In storage areas it is advisable to observe non-smoking restrictions.

Packing and transportation:

| Packing way | Packed in roll or flat sheet,50-100kg/roll or according to specific requests from clients |

| Packing material | Inner PE film+ outer Woven plastic bags as standard, palletized for extra reinforcement if necessary |

| Shipping marks | Neutral packing with printed marks. |

| Delivery time | 15 days since receipt of PO and down payment |

| Freight | Sea(FCL & LCL) or air freight |

| Special size | We provide cutting services for special sizes |

| Lamination | We provides extra lamination with PSA, textiles or other materials. |

FAQ(Frequently Asked Questions)1. What is the capability of your company ?Skypro is a professional manufacturer of rubber sheet for more than two decades.Top 10 biggest rubber factory in China.2.What is production capability each year?We produce more than 18000 tons of rubber sheet products each year.3.How can I get some samples?We are pleased to offer you free samples. New clients are expected to pay for the delivery cost, this charge will be deducted from the payment for formal order.

About Rubber

| rubber variety(ASTM ) | IR | SBR | BR | CR | NBR | |

| chemical structure | Isoprene Rubber,Cis 1,4- Polyisoprene “Synthetic Natural Rubber” | Styrene Butadiene Rubber | Polybutadiene Rubber | Poly-2-chlorobutadiene -1,3 chloroprene Rubber, Neoprene | Butadiene Acrylnitrile Rubber,Nitrile Rubber | |

| main characteristics | high flexibility, good comprehensive physical mechanic performance | better wear-resistant and anti-aging function than NR, lower prices | same wear-resistant with NR and better flexible and lower temperature resistant than NR | good climate resistant, ozone proof, hot resistance and chemical resistant | good oil-resistant, wear-resistant and anti-aging | |

| quality of NR | proportion | 0.93 | 0.94 | 0.93 | 1.23 | 0.96~1.02 |

|

meni adhesive meni adhesive ML 1+4 100 ℃ |

45 ~150 | 30~ 7 0 | 35~55 | 45~120 | 30~100 | |

| rubber physical performance |

hardness range ( SHORE A ) |

2 0~100 | 4 0~100 | 30~100 | 45~120 | 30~130 |

| anti-tensity (MPa) | 7~27 | 7~24 | 7~20 | 7~27 | 7~27 | |

| elongation rate (%) | 100~ 700 | 100~ 700 | 100~ 700 | 100~ 600 | 100~700 | |

| re-elasticity | excellent + | good | excellent + | excellent | good | |

| tearing force | excellent | middle ~ good | good | good | good | |

| wear-resistant | excellent | excellent | excellent | excellent | excellent | |

| compress & distortion | good | good | middle | good | good | |

| temperature range(℃) | -75~90 | -60~100 | -100~100 | -50~120 | -50~120 | |

| climate resistant | middle | middle | middle | excellent | bad | |

| ozone proof | bad | middle | bad | good ~ excellent | middle | |

| electric performance | excellent | middle | good | good | bad ~ middle | |

| gas penetrating resistant | middle | middle | middle | good | excellent | |

| oil-resistant and acid& alkali resistant | oil-resistant | bad | bad | bad | good | excellent |

| fire-resistant | bad | bad | bad | middle | good | |

| alcohol | excellent | excellent | excellent | excellent | excellent | |

| MEK | good | good | good | good | middle | |

| water | excellent | good ~ excellent | bad | good | excellent | |

| high concentration inorganic acid | middle | bad | bad | middle | middle | |

| low concentration inorganic acid | good | good | good | excellent | good | |

| high concentration alkali | good | good | good | excellent | good | |

| low concentration alkali | good | good | good | excellent | good | |

| application | tyre, rubber shoes, rubber pipe, adhesive tape, air spring | tyre, rubber shoes, rubberized fabrics, sports products, mattress, accumulator shell, adhesive tape | car & air plane tyre, rubber shoes, shock absorber rubber, adhesive tape, rubber pipe | wire sleeve, conveying line shock absorber rubber, window & door wedge, rubber adhesives, rubberized fabrics | oil seal, washer, oil-resistant rubber pipe, printing rubber roller, textile leather roller | |

| rubber variety(ASTM ) | EPDM | IIR | CSM | SIR | FKM | |

| chemical structure | Ethylene Propylene Terpolymer Rubber | Isobutene-Isoprene (butyl) Rubber | Chlorosulfonated Polyethyelene | Silicone Rubber | Vinylidene Fluoride Hexaflyoropropylene Rubber,Viton | |

| main characteristics | good anti-aging, ozone proof, polar liquid resistant, good electric performance, lightest rubber | good climate resistant, ozone proof, gas penetrating resistant, polar solvent resistant | better wear-resistant and anti-aging function than NR, lower prices. | good cold & hot resistant | best hot resistant and chemical resistant | |

| quality of NR | proportion | 0.85 | 0.91~0.93 | 1.10 | 0.98 | 1.4~1.96 |

| meni adhesive ML1+4 100 ℃ | 40~100 | 45~80 | 45~60 | liquid state | 35~160 | |

| rubber physical performance | hardness range ( SHORE A ) | 30~100 | 20~90 | 50~95 | 20~95 | 60~90 |

| anti-tensity (MPa) | 7~20 | 7~20 | 7~20 | 3~10 | 7~16 | |

| elongation rate (%) | 100~300 | 100~700 | 100~500 | 50~800 | 100~350 | |

| re-elasticity | good | middle | good | good | middle | |

| tearing force | bad | excellent | good | middle | middle | |

| wear-resistant | good | good | good | middle | good | |

| compress & distortion | middle | middle | good | excellent | excellent | |

| temperature range(℃) | -60~150 | -60~150 | -60~150 | -120~280 | -50~300 | |

| climate resistant | excellent | excellent | excellent | excellent | excellent | |

| ozone proof | excellent | excellent | excellent + | excellent | excellent + | |

| electric performance | excellent | excellent | good | excellent | good ~ excellent | |

| gas penetrating resistant | middle | excellent | less good | bad | excellent | |

| oil-resistant and acid& alkali resistant | oil-resistant | bad | middle | good | middle | excellent |

| fire-resistant | bad | bad | middle | bad | excellent | |

| alcohol | excellent | excellent | excellent | excellent | excellent | |

| MEK | good | excellent | less good | excellent | middle | |

| water | excellent | excellent | good ~ excellent | excellent | good ~ ecellent | |

| high concentration inorganic acid | good | excellent | excellent | good | excellent | |

| low concentration inorganic acid | excellent | excellent | excellent | excellent | excellent | |

| high concentration alkali | excellent | excellent | excellent | excellent | excellent | |

| low concentration alkali | excellent | excellent | excellent | excellent | excellent | |

| application | wire sleeve, auto weather strip, window & door wedge, steam rubber pipe, conveying line | interior tyre, sulfuration capsule, roof materials, wire sleeve, window & door wedge, steam rubber pipe, hot resistant conveying line | climate resistant, anti-corrosion coating, tank lining, outdoor rubberized fabrics, anti-corrosion axe seal, rubber roller | axe seal, washer, industrial rubber roller, shock absorber product, insulation products, medical products | axe seal used in rocket, missile, septum, tank lining, front pipe and pump fittings used in chemical factory | |

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for High Quality Rubber Roll Sheet - Insulation Natural Latex Rubber Sheets High Temp Anti – abrasion Thick Petrol Resistant – Skypro , The product will supply to all over the world, such as: Marseille, Boston, Sevilla, Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective solutions and meticulous after-sales service. We firmly believe that: we're outstanding as we have been specialized.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.